Stock shape taken from a childs .22 bolt action rifle, a Stevens Model 15, then modified to fit.

Brass pieces left over from a H&A Spanish rifle, butt, trigger guard, etc.

Cherry, 2 inches thick, a bit soft but seems to work OK.

During a rain storm today, got most of the barrel inlet. Some of you will recognize the barrel brand, about 18 inches long of what's left. Barrel chamber stub removed, flat filed on right side for a flintlock, yes that one. Now breached at 3/8-16. If this barrel does not work out then it can be bored out for a bit larger bore smoothie.

Aug/10/2016

Butt Plate installed. More shaping done but not finished.

Trigger guard modified to fit this stock.

Barrel plugged. Now for a hook breech tang, would be nice if it was brass but may end up as steel.

Aug/12/2016

Went to the local metal store, AZ-Metals. Bought a foot of 2x3x0.188 angle steel. Turns out it's ASTM A36, whatever that is. I also had them cut a 1 inch wide piece from that foot long. After about 1 hour I had what you now see. Top corners of the tang need trimming, also the tang needs a "bit" of bending.

It is going to be over 100F today and the shed gets too hot to work out there for more than 1-2 hours. My do-rag hanky is hanging in the bathroom curtain rod trying to dry out.

It is too bad that the barrel looks like a 10-22, argh.

OK, thanks to an idea by Tim Crosby on the AmericanLongRifles forum, I now have a touch hole insert. Stainless 1/4-20 and 1/4 inch long allen set screw inserted backwards, with a 1/16 inch diameter hole drilled through it. Set screw probably needs to be a bit longer as this one only gave 4.5 full threads out of 7 threads available in the barrel.

Shown here is the hook breech partly installed with temporary screws into the Cherry stock. Now for a barrel band or a wedge to hold the front of the barrel down.

Aug/13/2016

Pinned the barrel front.

Folded brass soldered to the barrel. Pinned with 3/32 inch wire (old coat hanger).

Lock comes next.

Aug/16/2016

Lock in.

Barrel in.

Trigger in.

Trigger guard on.

Flint in.

Sparks made.

Simulated left side plate.

To do:

Test Fire.

Walnut stock nose.

Side Plate.

Aug/17/2016

Beginnings of the side plate. Still a bit large.

Side plate hammered from the backside to "round it out".

Range Report:

Aug/20/2016

25 yards, 10grains of Goex FFFg, prime was Schuetzen FFFg, 0.22 caliber air gun pellets that I found at the range on the ground.

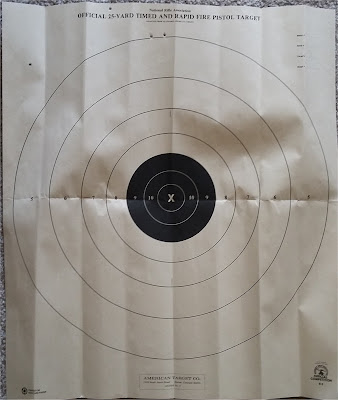

Large Target

Four hits upper area, about 10 to 11 inches high from the POA at dead center of the target.

Closer View:

During the fourth shot, it would not spark at all (argh). I changed the flint, not needed but it had to go off so that the public range could go cold. After about three more tries it finally went poof. That darned frizzen again. Time for a new one.

New frizzen ordered on flea-bay.

Notes:

I don't care about speed of the bullet, just that this rifle functions. Since it's my first hand-made flinter I am happy with it as is. The choice of wood is not good, this piece of Cherry is way too soft for a rifle stock, it keeps cracking and the sharp edges keep flaking away, disappointing.

Aug/22/2016

Ordered NAA black powder bullets today, 100 each. These are made for their NAA black powder .22 revolver and they should work fine in this rifle.

Made a tool to concave the backend of pulled .22 bullets. Lots of mis-fired ones at the range.

Aug/23/2016

Blued the tang, changed screws, etc. Length is 33.5 inches long, that's all, butt to muzzle.

33.5 inches long. Camera angle shows it all wrong.

Questions about the ramrod used; what? materials?

Core of the ramrod is steel of 0.156 inch or 5/32 inch diameter, outer is 0.187 or 3/16 inch hobby brass tubing, then a .22 caliber jag, all soldered together into one solid piece, jag end up against the steel rod. Jag is permanent.

Stainless rod with a brass brush for .22 cal, used after every shot.

Range Report: Aug/31/2016

Was able to get 16 shots before it got too hot at the range (AZ). Shoots a bit high. The barrel is so-so, either it's me or the barrel is not good for muzzle loading applications, too fast of a spin. Groups of 2 to 3 inches at 25 yards seem to be normal. This grouping is with 10gr of Goex FFFG, NAA bullets and some or no lube. Cleaning with a brass brush after each shot seems to be required. Using less than 10gr of Goex doesn't seem to help accuracy. It's a bit of a pain to load 10gr of BP from a large horn, spilling more than used.

The lock works fine if the flint is kept right up against the frizzen at half-cock. Once it wears down the lock starts to not spark. I can work with that. Frizzen spring seems to work fine.

The touch hole liner as it exists works fine, amazing.

Sept/08/2016

Range time today.

Have reduced the main charge to 7gr of Goex FFFg. Groups seem smaller.

Will be picking up a can of Goex FFFFg for testing, someday.

Keeping the flint up close to the frizzen and sharp, works. This lock is a flint eater, bummer.

Sept/15/2016

Range Report:

Benchrest at 25 yards, 7.5gr of Goex FFFg, no patches.

That 7.5gr is estimated by moving the marker to halfway between 5 and 10 on the brass powder measure.

All holes are those NAA BP bullets, except one.

The single hole just to the left of the "X" is a round-nose air-gun pellet of unknown weight and manufacture.

I talked to one of the air-gun fellas at the range, he suggested to try some JSB 18gr air-gun pellets of which he let me have three. The three holes to the targets left are those pellets. The three holes on the right are 14.3gr pellets. Same distance, same powder charge, no changes.

I rezsized the pellets through another 10-22 barrel before trying to push them down the muzzle of this rifle. That helped to keep the pellet skirts intact and correctly sized.

When I got home I moved the trigger pivot to the new location shown by the shiney pin showing just under the rear lock screw. Now the trigger pull is around 3 lbs instead of what it was and terrible it was! Trigger was flattened a bit to accomodate the internal vertical move. Plug that old hole!

Sept/21/2016

Removed broken rear sight and replaced it with a 1/16 inch diameter brass peep sight.

The peep hole has been countersunk on both sides to reduce internal reflections from the AZ sunshine.

Sept/22/2016

Some embelishment on the lock plate.

Frizzen spring finished, now locks the frizzen open.

Oh look, another one:

https://youtu.be/rFfsBZURIdQ

Building an iron flintlock lock:

http://americanlongrifles.org/forum/index.php?topic=26825.0

IdeZilla

Comments Welcomed