Stock and barrel marked with the "K". This will be my first flinter.

Not really assembled yet as the wedge is not installed because the barrel underlug is missing. Rib screws also missing, etc. Rear sight is missing the spring and adjustment screw, removed until the parts are found.

It has an agate rock which does not want to spark.

Barrel serial number starts with that "K" and is six digits long. Stock barrel channel similarly marked "K".

Stock has one coat of Tru-Oil. Hook breach.

Bore is clean. Re-blued parts of the barrel. Barrel had been sanded to see the stampings (not by me).

Range Report: Sept/24/2015

25 yards, 45gr Goex FFFg, prime with same, 0.440 RB, blue ticking patch with bore-butter lube.

First time for having and shooting a flinter, ever.

First hit just below the wedge on the top target.

Various hits on the top target while trying to sight in. Moving the rear sight up/down/left.right.

Lower target was next. The two red hits top edge of red area were the last two shots for the day.

I did run out of Goex FFFg and tried another unknown FFFg, had various fails to fire. I will make sure that the powder is always Goex or Schuetzen and not a "substitute".

---

All cleaned up with just water, fun stuff.

---

I am not used to the slight delay between flash and boom. I have always been shooting underhammers and this flinter delay will take some getting used to. I don't expect this lock to be very fast as it's a "consumer model".

---

Now that I know that this one is a shooter, I can finish cleaning up the stock, brasses, etc. There is a large gap between the stocks barrel channel and the right side of the barrel letting flash hole gasses down into the lock innards. This will get fixed pronto. The lock isn't absolutely tight against the barrel, will have to inlet the front area of the lock a bit more. (Done)

Touch Hole Liner, coned inside, 1/4" x 28. Installed with high-temp anti-seize.

Newly refreshed frizzen (I hope it works now). Sept/25/2015

New flint, new leather.

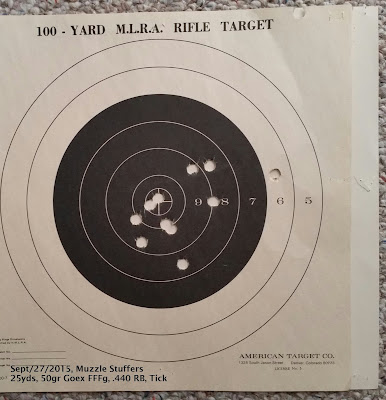

Range Report, Sept/27/2015

25yds, 50gr Goex FFFg, .440 and .445 RB's, Blue Tick Patches.

Putting a double piece of thick leather under the flint+wrap elevated the flint to hit the frizzen a bit higher. It seemed to shorten the apparent firing "delay".

My rear sight elevator kept moving up/down and I didn't notice it until I got home cleaning the barrel.

Hence the vertical movements. I need a stronger elevator spring and proper elevator screw. Will order same online.

Here the sight was too low and shots kept moving down, to my dismay.

Oct/15/2015

25 yards, 50 gr of Schuetzen FFFg, .445 RB, ticking patch.

First shot, far left. Next three bottom right. Adjusted rear sight, shot all of the rest. Some .440 some .445 RB's, some ticking and some commercial patches. I like the two red dot hits.

Had some trouble with the patent breech, kept filling up with residue during loading, ggrrr!!! It would take 3 to 5 re-primes to get it to go off using 1/2 pan of powder. Would love to remove that patent breech and make it a flat faced breech, making it easier to clean. The red dot groups; not sure if the lower group is 3 or 4 hits, I lost count.

Comparison of old lock to newer lock. I have the old one (lower) and am looking for the new one (upper), or maybe just the complete hammer(cock).

Oct/22/2015 On-Going Range Reports

12 x 18 inch target - $1 at the range, 25 yards, 0.440 RB, Tick patch, Schuetzen FFFg main and prime.

First three shots were the wild ones around the center.

Then slowly walked the shots up and to the left ending above the center.

Last shots were the head shots (6+ or so), finally shooting higher that the POA.

That darn rear sight elevation screw kept moving (again) and needs a really strong elevation spring to keep the screw from moving. Or maybe some paper tape :-)

I was having trouble with that patent breech and the brand of powder being a bit dirty. I used a .30 caliber brass brush to help in cleaning out that breech pocket. Helped save the day.

If after a pan flash but no boom, I would trickle powder into the pan and tilt the rifle to the left to tap some through the touch hole, trying to get some more powder behind the main charge. Then refill the pan and shoot. This works for me.

Range Report: Oct/25/2015

25 yards, 50gr of Goex FFFg, Blue Tick patch, Home-poured .440 RB's, some Hornady .440 RB's.

First three was learning the routine and sighting in (again) as the front sight keeps moving sideways.

Practice bull, 4 shots. upper left dirty-bird, 6 shots 5 near center.

Upper right dirty-bird 8 shots, was testing Hornady against home-poured RB's.

Upper left dirty-bird, 1 shot, upper right dirty-bird started with 1 shot upper right edge of red bull,

lower target bull, 1 shot. I think I have it for now. Went back to upper right dirty-bird and shot 4 more.

I will be adding a set-screw to the front sight to keep it in place.

Done.

Range Report: Oct/29/2015

25 yards, Goex FFFg 50gr, main and prime .440 RB hand-poured, blue tick patch.

As day progressed, shots got better and I relaxed too which helps.

Lost count of shots used. Looks like left target = 10 shots, right target = 16 shots.

Range Report on new parts, Nov/05/2015

Goex FFFg main, Schuetzen FFFg prime, 0.440 Hornady RB, 0.018 inch thick Blue ACA Ticking Patch, 25 yards.

Targets as hung/stapled on target backer.

Left Target: 5 shots

Right Target: Belly 5 shots, Head 5 shots, left small 3 shots, right small 3 shots.

Pink flag/ribbon, left over from air gun shooters.

Sights did not voluntarily move this outing, Yay!

50 yards will be the next setup.

IdeZilla

Comments Welcomed.