I had two revolvers, both not very useable. The best parts were used to make one revolver.

Barrel and Cylinder are from a 1851 style Spesco .36 caliber brass frame, date code XXVI. This barrel is clean with no rust or pitting in the bore.

This frame is a 1862 type steel frame, DGG (Armi San Paolo), date code [AF], with the rifle stock notches and screws.

I'll try to put up better pictures when it's sunny outside.

Here is the resulting revolver.

The barrel would not move all of the way back to eliminate that massive cylinder gap. A small amount of metal was removed from where the two pins align the barrel and frame. The cylinder gap is now very small.

The wedge gap was moved forward in the barrel portion to accomodate the barrel setback.

The cylinder locks up very nicely and is much better than the original

off-center fluted 1860 cylinder.

This particular cylinder has two sizes

in its bores. One half takes a .375 RB while the other half takes a

.380 RB, not sure how that happened. It was before my time, I'm sure.

Here is that cylinder with the (pictures) left side showing .375 RB and the right side showing .375 RB. I have marked the three large bores with an "O", for quick reloading.

The cylinder does not have those safety pins between nipples for a safe position.

The barrel before the metal removal modification.

Current parts:

The left over parts:

Brasser frame has had a soldered on steel washer added to partly eliminate cylinder/brass-frame smashing.

All Parts:

Results:

Range Report:

Apr/29/2016:

During shooting, the existing barrel wedge loosened up enough so that I had to stop as the cylinder gap was too much. Several times the loading lever would drop down further aggravating the shooter.

After cleaning said revolver, a new wedge was made. Longer and wider. Started with a piece of 2 inch web angle iron (steel). For thinning, several hack-saw cuts were made then HF files went to work to smooth the wedge.

The barrel notch on the left side was moved forward.

Here for comparison are the two wedges.

Notice how beat up the one on the right is, the original one. New one is on the left. No spring or screw groove, yet.

New wedge installed. Only thumb tight, no more. No hammering here.

Top view of new wedge. Plenty of length left for tightening said wedge.

The portion sticking out of the right side can now be shortened, for looks only. More gun blueing will be added as soon as the shooter can get to the appropriate store.

Holster:

http://idezilla.blogspot.com/2016/07/holster-for-that-spescodgg-revolver.html

IdeZilla

Comments Welcomed.

Wednesday, April 27, 2016

Thursday, January 21, 2016

Cross Sticks

I decided to try and make an inexpensive version of Cross Sticks / X-Sticks.

Used them today for sitting 50yds testing.

It folds up nicely with the leather still attached.

This setup is for sitting, at my body size.

Hard part (at my age) is the sitting down, shooting the one shot, then getting back up for the reload.

These sticks, when stuck into the ground, stayed up for the duration of the outing even with a brisk wind blowing.

Parts:

1.5 x 0.75 inch Alder, 36 inches long, two each, all edges rounded. I hate splinters.

2 inch long 1/4 x 20 bolt and wingnut with two fender washers.

Holes to clear the bolt, spaced at approximately 1 inch intervals.

A piece of heavy leather for the padding.

Points at the bottom were large 6 inch dry-wall type screws, installed, the screw heads were then cut away and then the ends were sharpened.

IdeZilla

Comments Welcomed.

Used them today for sitting 50yds testing.

It folds up nicely with the leather still attached.

This setup is for sitting, at my body size.

Hard part (at my age) is the sitting down, shooting the one shot, then getting back up for the reload.

These sticks, when stuck into the ground, stayed up for the duration of the outing even with a brisk wind blowing.

Parts:

1.5 x 0.75 inch Alder, 36 inches long, two each, all edges rounded. I hate splinters.

2 inch long 1/4 x 20 bolt and wingnut with two fender washers.

Holes to clear the bolt, spaced at approximately 1 inch intervals.

A piece of heavy leather for the padding.

Points at the bottom were large 6 inch dry-wall type screws, installed, the screw heads were then cut away and then the ends were sharpened.

IdeZilla

Comments Welcomed.

Thursday, November 5, 2015

Frizzen Resole

Nov/05/2015

I have this original (to the rifle) frizzen that has plagued me. I could not reharden it at all, have tried many times, even with a newly purchased hardening/carbon infusing compound. So, tonight after browsing Americal Longrifles Forum, I found a statement that basically said "old files spark the greatest" or something like that. I had kept a pile of old Chinese H.F. files that were worn out. So I broke off a piece. With my 6" wide belt sander, ground one face to fit the contours of that horrible frizzen's face. Since the frizzen was already tinned (soft-solder with 3% silver content) This file piece could be sweated to the frizzen. After the sweating, the face was ground to simulate the frizzen curve. It is a bit thicker, but it should outlast me and several more generations to follow.

After sweating, left edge.

The added piece shape was already defined before this stage. When soldering, the solder will use capillary action to try and center the two parts, no need to clamp anything.

The file was not tempered. I had decided to try and keep it as hard as possible.

Other side,edge.

Here is seen the old file face.

Darn thing slid up a bit but it'll still work fine. If I had wired it into place this would not have happened.

Now to surface grind the "file piece".

A bit fuzzy, but the solder joint can be seen.

During surface grinding. The edges have already been trimmed but not finished.

A bit of the old file edge can be seen here along with that solder joint. Yes, the joint is a bit thick but it should hold just fine.

Finished with surface grinding. Nice and smooth, a long ways better than that old hacked up face underneath. Front edges have been slightly rounded to keep from cutting the user.

Installed! This is a monumentous achievement for me. This gives me a spare frizzen, one was bought on ebay and now will be retired. Plus this resoled one sparks nice hot stuff that bounces around. What a relief.

Now I can rest, knowing that this can be done with cheap worn out files from China.

Nov/08/2015

Frizzen worked fine, solder joint held up, no breakage.

Not enough sparks, file resole piece was too hard. Heated the file resole piece to straw color. Tried it, more sparks, much better.

Nov/14/2015

Changed out the file piece for another piece. File handle stamped (Eagle) CNCO.

Works better than Nov/08 piece. Hardened and drawn back before attaching.

Sept/01/2016

None of the above lasts very long.

Finally riveted a piece of old saw blade to that frizzen. Tempered the piece and it works much better. Will be kept as a "backup" frizzen.

IdeZilla

Comments Welcomed

I have this original (to the rifle) frizzen that has plagued me. I could not reharden it at all, have tried many times, even with a newly purchased hardening/carbon infusing compound. So, tonight after browsing Americal Longrifles Forum, I found a statement that basically said "old files spark the greatest" or something like that. I had kept a pile of old Chinese H.F. files that were worn out. So I broke off a piece. With my 6" wide belt sander, ground one face to fit the contours of that horrible frizzen's face. Since the frizzen was already tinned (soft-solder with 3% silver content) This file piece could be sweated to the frizzen. After the sweating, the face was ground to simulate the frizzen curve. It is a bit thicker, but it should outlast me and several more generations to follow.

After sweating, left edge.

The added piece shape was already defined before this stage. When soldering, the solder will use capillary action to try and center the two parts, no need to clamp anything.

The file was not tempered. I had decided to try and keep it as hard as possible.

Other side,edge.

Here is seen the old file face.

Darn thing slid up a bit but it'll still work fine. If I had wired it into place this would not have happened.

Now to surface grind the "file piece".

A bit fuzzy, but the solder joint can be seen.

During surface grinding. The edges have already been trimmed but not finished.

A bit of the old file edge can be seen here along with that solder joint. Yes, the joint is a bit thick but it should hold just fine.

Finished with surface grinding. Nice and smooth, a long ways better than that old hacked up face underneath. Front edges have been slightly rounded to keep from cutting the user.

Installed! This is a monumentous achievement for me. This gives me a spare frizzen, one was bought on ebay and now will be retired. Plus this resoled one sparks nice hot stuff that bounces around. What a relief.

Now I can rest, knowing that this can be done with cheap worn out files from China.

Nov/08/2015

Frizzen worked fine, solder joint held up, no breakage.

Not enough sparks, file resole piece was too hard. Heated the file resole piece to straw color. Tried it, more sparks, much better.

Nov/14/2015

Changed out the file piece for another piece. File handle stamped (Eagle) CNCO.

Works better than Nov/08 piece. Hardened and drawn back before attaching.

Sept/01/2016

None of the above lasts very long.

Finally riveted a piece of old saw blade to that frizzen. Tempered the piece and it works much better. Will be kept as a "backup" frizzen.

IdeZilla

Comments Welcomed

Monday, October 26, 2015

New parts for that Hawken .45 cal flinter

Installed, a newer cock replacing the older one on a .45 cal T/C Hawken.

This newer cock does not have the hook in it's profile on the left side.

The flint is the same color as the carpet, sorry. This particular flint is quite thin. I'm hoping that it lasts longer with this new part.

Next would be weakening the main coil spring in hopes of lessening the flint bashing of this lock.

The flint is about 1/16 inch away from the frizzen. A thick piece of leather raises the flint up about 3/16 inch. Flint is wrapped with black pigskin.

Underneath shows the flint heighth in relation to the frizzen. Much higher than the older cock. The jaw screw and upper jaw are original and fit.

Old style cock, there is a S-hook in the profile on the left side, just above the screw. Yes, that flint is toast. I compared the two cock sizes and I can only guess that the newer one is about 3/16 inch taller.

Next, fix the loose front sight. Yup, a 4-40 x 1/4 inch long set screw installed into this now really ugly front sight. It won't move now. It still looks the same from the rear.

Who made this barrel?

Green Mountain?

Date?

.45 cal really thin rifling. No safety stampings anywhere.

Circle-M stamping on the bottom of said barrel.

Range Report, Nov/05/2015

25 yards, Goex FFFg main, Schuetzen FFFg prime, 0.0440 Hornady RB, 0.018 inch Blue ACA Ticking patch.

Targets as stapled to target backer.

Left Target: 5 shots.

Right Target: Belly 5 shots, Head 5 shots, left small 3 shots, right small 3 shots.

Now to get ready for 50 yard practice.

IdeZilla

Comments Welcomed

This newer cock does not have the hook in it's profile on the left side.

The flint is the same color as the carpet, sorry. This particular flint is quite thin. I'm hoping that it lasts longer with this new part.

Next would be weakening the main coil spring in hopes of lessening the flint bashing of this lock.

The flint is about 1/16 inch away from the frizzen. A thick piece of leather raises the flint up about 3/16 inch. Flint is wrapped with black pigskin.

Underneath shows the flint heighth in relation to the frizzen. Much higher than the older cock. The jaw screw and upper jaw are original and fit.

Old style cock, there is a S-hook in the profile on the left side, just above the screw. Yes, that flint is toast. I compared the two cock sizes and I can only guess that the newer one is about 3/16 inch taller.

Next, fix the loose front sight. Yup, a 4-40 x 1/4 inch long set screw installed into this now really ugly front sight. It won't move now. It still looks the same from the rear.

Who made this barrel?

Green Mountain?

Date?

.45 cal really thin rifling. No safety stampings anywhere.

Circle-M stamping on the bottom of said barrel.

Range Report, Nov/05/2015

25 yards, Goex FFFg main, Schuetzen FFFg prime, 0.0440 Hornady RB, 0.018 inch Blue ACA Ticking patch.

Targets as stapled to target backer.

Left Target: 5 shots.

Right Target: Belly 5 shots, Head 5 shots, left small 3 shots, right small 3 shots.

Now to get ready for 50 yard practice.

IdeZilla

Comments Welcomed

Tuesday, September 15, 2015

Hawken Flintlock, a kit in pieces, with ongoing range reports.

I picked up a Hawken flinter in pieces for $100. It needs the barrel lug and the screws for the rail, etc.

Stock and barrel marked with the "K". This will be my first flinter.

Not really assembled yet as the wedge is not installed because the barrel underlug is missing. Rib screws also missing, etc. Rear sight is missing the spring and adjustment screw, removed until the parts are found.

It has an agate rock which does not want to spark.

Barrel serial number starts with that "K" and is six digits long. Stock barrel channel similarly marked "K".

Stock has one coat of Tru-Oil. Hook breach.

Bore is clean. Re-blued parts of the barrel. Barrel had been sanded to see the stampings (not by me).

Range Report: Sept/24/2015

25 yards, 45gr Goex FFFg, prime with same, 0.440 RB, blue ticking patch with bore-butter lube.

First time for having and shooting a flinter, ever.

First hit just below the wedge on the top target.

Various hits on the top target while trying to sight in. Moving the rear sight up/down/left.right.

Lower target was next. The two red hits top edge of red area were the last two shots for the day.

I did run out of Goex FFFg and tried another unknown FFFg, had various fails to fire. I will make sure that the powder is always Goex or Schuetzen and not a "substitute".

---

All cleaned up with just water, fun stuff.

---

I am not used to the slight delay between flash and boom. I have always been shooting underhammers and this flinter delay will take some getting used to. I don't expect this lock to be very fast as it's a "consumer model".

---

Now that I know that this one is a shooter, I can finish cleaning up the stock, brasses, etc. There is a large gap between the stocks barrel channel and the right side of the barrel letting flash hole gasses down into the lock innards. This will get fixed pronto. The lock isn't absolutely tight against the barrel, will have to inlet the front area of the lock a bit more. (Done)

Touch Hole Liner, coned inside, 1/4" x 28. Installed with high-temp anti-seize.

Newly refreshed frizzen (I hope it works now). Sept/25/2015

New flint, new leather.

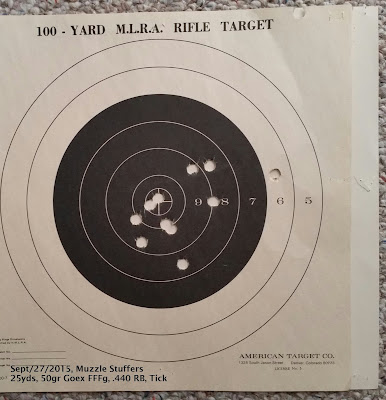

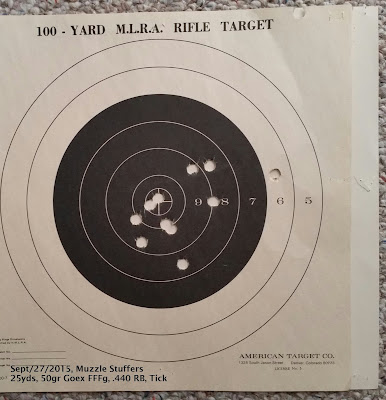

Range Report, Sept/27/2015

25yds, 50gr Goex FFFg, .440 and .445 RB's, Blue Tick Patches.

Putting a double piece of thick leather under the flint+wrap elevated the flint to hit the frizzen a bit higher. It seemed to shorten the apparent firing "delay".

My rear sight elevator kept moving up/down and I didn't notice it until I got home cleaning the barrel.

Hence the vertical movements. I need a stronger elevator spring and proper elevator screw. Will order same online.

Here the sight was too low and shots kept moving down, to my dismay.

Oct/15/2015

25 yards, 50 gr of Schuetzen FFFg, .445 RB, ticking patch.

First shot, far left. Next three bottom right. Adjusted rear sight, shot all of the rest. Some .440 some .445 RB's, some ticking and some commercial patches. I like the two red dot hits.

Had some trouble with the patent breech, kept filling up with residue during loading, ggrrr!!! It would take 3 to 5 re-primes to get it to go off using 1/2 pan of powder. Would love to remove that patent breech and make it a flat faced breech, making it easier to clean. The red dot groups; not sure if the lower group is 3 or 4 hits, I lost count.

Comparison of old lock to newer lock. I have the old one (lower) and am looking for the new one (upper), or maybe just the complete hammer(cock).

Oct/22/2015 On-Going Range Reports

12 x 18 inch target - $1 at the range, 25 yards, 0.440 RB, Tick patch, Schuetzen FFFg main and prime.

First three shots were the wild ones around the center.

Then slowly walked the shots up and to the left ending above the center.

Last shots were the head shots (6+ or so), finally shooting higher that the POA.

That darn rear sight elevation screw kept moving (again) and needs a really strong elevation spring to keep the screw from moving. Or maybe some paper tape :-)

I was having trouble with that patent breech and the brand of powder being a bit dirty. I used a .30 caliber brass brush to help in cleaning out that breech pocket. Helped save the day.

If after a pan flash but no boom, I would trickle powder into the pan and tilt the rifle to the left to tap some through the touch hole, trying to get some more powder behind the main charge. Then refill the pan and shoot. This works for me.

Range Report: Oct/25/2015

25 yards, 50gr of Goex FFFg, Blue Tick patch, Home-poured .440 RB's, some Hornady .440 RB's.

First three was learning the routine and sighting in (again) as the front sight keeps moving sideways.

Practice bull, 4 shots. upper left dirty-bird, 6 shots 5 near center.

Upper right dirty-bird 8 shots, was testing Hornady against home-poured RB's.

Upper left dirty-bird, 1 shot, upper right dirty-bird started with 1 shot upper right edge of red bull,

lower target bull, 1 shot. I think I have it for now. Went back to upper right dirty-bird and shot 4 more.

I will be adding a set-screw to the front sight to keep it in place.

Done.

Range Report: Oct/29/2015

25 yards, Goex FFFg 50gr, main and prime .440 RB hand-poured, blue tick patch.

As day progressed, shots got better and I relaxed too which helps.

Lost count of shots used. Looks like left target = 10 shots, right target = 16 shots.

Range Report on new parts, Nov/05/2015

Goex FFFg main, Schuetzen FFFg prime, 0.440 Hornady RB, 0.018 inch thick Blue ACA Ticking Patch, 25 yards.

Targets as hung/stapled on target backer.

Left Target: 5 shots

Right Target: Belly 5 shots, Head 5 shots, left small 3 shots, right small 3 shots.

Pink flag/ribbon, left over from air gun shooters.

Sights did not voluntarily move this outing, Yay!

50 yards will be the next setup.

IdeZilla

Comments Welcomed.

Stock and barrel marked with the "K". This will be my first flinter.

Not really assembled yet as the wedge is not installed because the barrel underlug is missing. Rib screws also missing, etc. Rear sight is missing the spring and adjustment screw, removed until the parts are found.

It has an agate rock which does not want to spark.

Barrel serial number starts with that "K" and is six digits long. Stock barrel channel similarly marked "K".

Stock has one coat of Tru-Oil. Hook breach.

Bore is clean. Re-blued parts of the barrel. Barrel had been sanded to see the stampings (not by me).

Range Report: Sept/24/2015

25 yards, 45gr Goex FFFg, prime with same, 0.440 RB, blue ticking patch with bore-butter lube.

First time for having and shooting a flinter, ever.

First hit just below the wedge on the top target.

Various hits on the top target while trying to sight in. Moving the rear sight up/down/left.right.

Lower target was next. The two red hits top edge of red area were the last two shots for the day.

I did run out of Goex FFFg and tried another unknown FFFg, had various fails to fire. I will make sure that the powder is always Goex or Schuetzen and not a "substitute".

---

All cleaned up with just water, fun stuff.

---

I am not used to the slight delay between flash and boom. I have always been shooting underhammers and this flinter delay will take some getting used to. I don't expect this lock to be very fast as it's a "consumer model".

---

Now that I know that this one is a shooter, I can finish cleaning up the stock, brasses, etc. There is a large gap between the stocks barrel channel and the right side of the barrel letting flash hole gasses down into the lock innards. This will get fixed pronto. The lock isn't absolutely tight against the barrel, will have to inlet the front area of the lock a bit more. (Done)

Touch Hole Liner, coned inside, 1/4" x 28. Installed with high-temp anti-seize.

Newly refreshed frizzen (I hope it works now). Sept/25/2015

New flint, new leather.

Range Report, Sept/27/2015

25yds, 50gr Goex FFFg, .440 and .445 RB's, Blue Tick Patches.

Putting a double piece of thick leather under the flint+wrap elevated the flint to hit the frizzen a bit higher. It seemed to shorten the apparent firing "delay".

My rear sight elevator kept moving up/down and I didn't notice it until I got home cleaning the barrel.

Hence the vertical movements. I need a stronger elevator spring and proper elevator screw. Will order same online.

Here the sight was too low and shots kept moving down, to my dismay.

Oct/15/2015

25 yards, 50 gr of Schuetzen FFFg, .445 RB, ticking patch.

First shot, far left. Next three bottom right. Adjusted rear sight, shot all of the rest. Some .440 some .445 RB's, some ticking and some commercial patches. I like the two red dot hits.

Had some trouble with the patent breech, kept filling up with residue during loading, ggrrr!!! It would take 3 to 5 re-primes to get it to go off using 1/2 pan of powder. Would love to remove that patent breech and make it a flat faced breech, making it easier to clean. The red dot groups; not sure if the lower group is 3 or 4 hits, I lost count.

Comparison of old lock to newer lock. I have the old one (lower) and am looking for the new one (upper), or maybe just the complete hammer(cock).

Oct/22/2015 On-Going Range Reports

12 x 18 inch target - $1 at the range, 25 yards, 0.440 RB, Tick patch, Schuetzen FFFg main and prime.

First three shots were the wild ones around the center.

Then slowly walked the shots up and to the left ending above the center.

Last shots were the head shots (6+ or so), finally shooting higher that the POA.

That darn rear sight elevation screw kept moving (again) and needs a really strong elevation spring to keep the screw from moving. Or maybe some paper tape :-)

I was having trouble with that patent breech and the brand of powder being a bit dirty. I used a .30 caliber brass brush to help in cleaning out that breech pocket. Helped save the day.

If after a pan flash but no boom, I would trickle powder into the pan and tilt the rifle to the left to tap some through the touch hole, trying to get some more powder behind the main charge. Then refill the pan and shoot. This works for me.

Range Report: Oct/25/2015

25 yards, 50gr of Goex FFFg, Blue Tick patch, Home-poured .440 RB's, some Hornady .440 RB's.

First three was learning the routine and sighting in (again) as the front sight keeps moving sideways.

Practice bull, 4 shots. upper left dirty-bird, 6 shots 5 near center.

Upper right dirty-bird 8 shots, was testing Hornady against home-poured RB's.

Upper left dirty-bird, 1 shot, upper right dirty-bird started with 1 shot upper right edge of red bull,

lower target bull, 1 shot. I think I have it for now. Went back to upper right dirty-bird and shot 4 more.

I will be adding a set-screw to the front sight to keep it in place.

Done.

Range Report: Oct/29/2015

25 yards, Goex FFFg 50gr, main and prime .440 RB hand-poured, blue tick patch.

As day progressed, shots got better and I relaxed too which helps.

Lost count of shots used. Looks like left target = 10 shots, right target = 16 shots.

Range Report on new parts, Nov/05/2015

Goex FFFg main, Schuetzen FFFg prime, 0.440 Hornady RB, 0.018 inch thick Blue ACA Ticking Patch, 25 yards.

Targets as hung/stapled on target backer.

Left Target: 5 shots

Right Target: Belly 5 shots, Head 5 shots, left small 3 shots, right small 3 shots.

Pink flag/ribbon, left over from air gun shooters.

Sights did not voluntarily move this outing, Yay!

50 yards will be the next setup.

IdeZilla

Comments Welcomed.

Sunday, July 5, 2015

Bench Rest 54

A Bench Rest .54 caliber "Rifle"

Range Report for Aug/28/2015 at bottom.Here is the start of a bench rest shooter. Action is from a well known website purchased second-hand. The hammer has been remade as the distance from the plug end to nipple was too much for the original hammer. I needed another 3/16 inch longer hammer. Hammer head is unfinished until the nipple is installed. Barrel is 1 + 1/8 inches across the flats and 35 inches long being .54 caliber with a 1:70 twist. The barrel maker is Sharon Rifle Barrel Co. Barrel plug is 3/4 inch x 16 threads/inch and the stub end is turned down to 5/8 inch to fit into the action block. Action block has three set screws (1/4 inch x 28 threads/inch) previously installed. Block also has a bushing installed to reduce the original quite large hole to 5/8 inch diameter.

After using this rifle several times not liking the current amount of drop, I will probably change the drop on the stock to much less. This means another stock and some more time in the "shop".

The tape and line drawn show the end of the plug.

The nipple will be just ahead of the drawn line.

Full size barrel.

Simulated stock in tracing paper.

Tracing paper stock and date.

July/06/2015

Cap Popped.

The background noise is my very large swamp cooler because it's 105F outside.

Cap Popping MP4

Cherry Stock from Timber Hardwoods, Mesa, AZ.

Through bolt installed (tang to trigger plate) a temporary one.

Now for front & rear sights and a whole bunch of wood trimming.

July/09/2015

Took her to the range today.

Got about 8 shots off then broke the rear sight away from the mount. Now repaired.

Standing up.

Laying Down.

What is left of a 1982 Peso. A bit ugly, for that rear sight to work this front sight needed the heighth.

Range Report: 25 yards, 55gr of Goex FFFg, 0,012 inch patch, .530 RB.

First shots high and up to the left. Remaining trying to sight her in.

One flyer near the bottom center???

May have to try .535 RB's or a thicker patch or both. Rifling is quite deep.

Me at 70 years old.

Lumpy bag to hold those .530 lead marbles.

I used glass marbles to stretch it out hence the lumps.

July/21/2015

Range time cut short by sharp edges on the muzzle crown.

So re-crowned and removed all sharp edges at the muzzle.

Will be using Denim and a choice of .530 or .535 Hornady RB's.

July/26/2015

Range Report on thick patches, reduced diameter Round Balls.10 patches are 0.030 thick, see next picture.

3 patches are 0.025 thick

2 patches are 0.015 thick.

I think the two upper left patches are a bit thinner, maybe 0.025 while the rest are 0.030 inches thick.

0.535 RB's pushed through a ~0.52 ID diameter pipe. These work, looks like I need 0.520 RB's for sure.

40 gr of 777 FFg, 25 yds

Red dots previous days shooting, burnt patches, 0.530 RB's.

Holes today July/26, two flyers are the burnt patches, center grouping 6 or 7 shots (?) not burnt patches.

July/29/2015

Today's Range Report and some other stuff.

I ran out of 0.530 and 0.535 RB's, bummer.

Lands, yes I know this is not the way to measure this stuff, but it gets me in the ballpark.

Looks like approximately 0.547 or so.

Grooves, looks like 0.572 approximately.

Two upper left patches my wife calls "Twill", around 0.022 inches. Rest are 0.030 denim.

Upper left patch was used to launch a .50 cal 385gr lubed Hornady hollowbase bullet.

Having fun with those funny shaped (belted or simulated 0.520) RB's.

I lost count. Yes, I tried to hit those four corner bulls.

25 yds, 60gr of 777 FFg.

All POI's were dead center.

I guess that it wasn't my day for 50 yds and everything just fell apart.

Hit just to the right of center is that Hornady 385gr bullet.

50yds, 60gr 777 FFg.

Aug/07/2015 Range Report.

Thicknesses or diameters all in inches.

50yds, 0.022 Bull Denim Patch, 55gr of 777-FFg, 0.530 RB's from my new 0.530 Lee mold.

All patches really soaked with lube.

Bull Denim is natural colored, not blue. It tends to ravel a lot.

Paper target on the right for starters

Mixture of 0.022 Bull Denim and 0.030 Blue Denim shots.

Aug/28/2015

Range Report

All Targets:

50 yards, .54 cal, .530 RB self-cast, 52gr of 777-FFg, Bull Denim Patches approx 0.021 inches thick, Hoppes 9 Plus lube.

Fuzzy pix.

First target with 11 shots.

Second Target.

Four+shots with two flyers.

I lost count of how many went through the clover-leaf hole, at least four.

Fuzzy pix.

Third Target.

8 shots for a 72. One patched back-hump shot is previous day. First two head shots were the wild ones. Then I settled down and aimed above the front leg. Rifle still shoots a bit to the left, probably just me. Rear sight is a bit too close to me and becomes fuzzy. I should move the rear sight down the barrel away from me.

Range Report: Sept/13/2015

Just one target. First time using (borrowed) X-Sticks and sitting on the ground. First time to shoot this rifle at 100yds. Five shots, four hit, first one 10 ring, the rest - well I got tired. Fifth, who knows?

Mar/10/2016

Working on adding a buttplate. It looks like Nickel-Silver and it's not magnetic. Found at a swap meet, $10-US. Brass screws show the contrast in color.

Getting ready for a sight tube.

The early mockup sitting on a metal box.

Tube is probably too long until the mounts arrive.

Stock has been cut at the narrowest area and glued/screwed back together.

This raises the butt about 1 inch.

IdeZilla

Comments Welcomed.

Subscribe to:

Posts (Atom)